By Okoti Gilbert, Kenya Sugar Board

Harvesting and transportation form a vital sector within the sugar industry, playing a significant role in determining production costs. Transporting sugarcane from the farm gate to the mills often attracts high costs due to the multiple transport facilities required and the time-consuming nature of the delivery process. Delays in transportation are a serious concern, as they impact production costs, which are ultimately reflected in the price paid by the consumer.

The Kenya Sugar Industry

Demand for sugar has risen drastically, resulting in increased sugarcane production and the expansion of sugar mills. Sugarcane cultivation and processing into raw sugar is among the largest industries in the country, with 15 mills established across different regions and an estimated 400,000 cane growers spread across five catchment areas. The prices paid to growers are determined by a formula set by the Sugarcane Pricing Committee.

Focus on Transport and Harvesting of Sugarcane

Most sugarcane growers in the region are small-scale farmers, who must bear the cost of transporting cane from their farms to the mills or to nearby loading stations for bulk carriers. They also have to hire laborers for cutting and loading the cane onto tractors. In addition, growers are taxed a cess—currently set at 1% per ton of cane delivered to the mill—for road maintenance. Unfortunately, the road network in the sugar catchment areas remains in poor condition due to inadequate maintenance.

Both mill owners and cane farmers are affected by transport operations. For example, during the off-season, mills often face an inadequate supply of raw materials for crushing because trucks must travel long distances to fetch under-capacity cane loads. This leads to higher transport costs, which are then reflected in the cane grower's statement.

Cutting, Loading, and Transporting Costs

Cutting and loading costs account for about 10% of the cost of a fully loaded flatbed truck, with the mill paying only 1% and the cane grower covering the remaining 9% plus other expenses, depending on the number of cutting days and trucks involved. Depending on the distance, farmers have to pay at least 20% per ton of the total. Combined, labor costs for cutting, loading, and transporting represent 30–40% of the total cost, which is a significant burden for small-scale growers.

The Loading Station Strategy

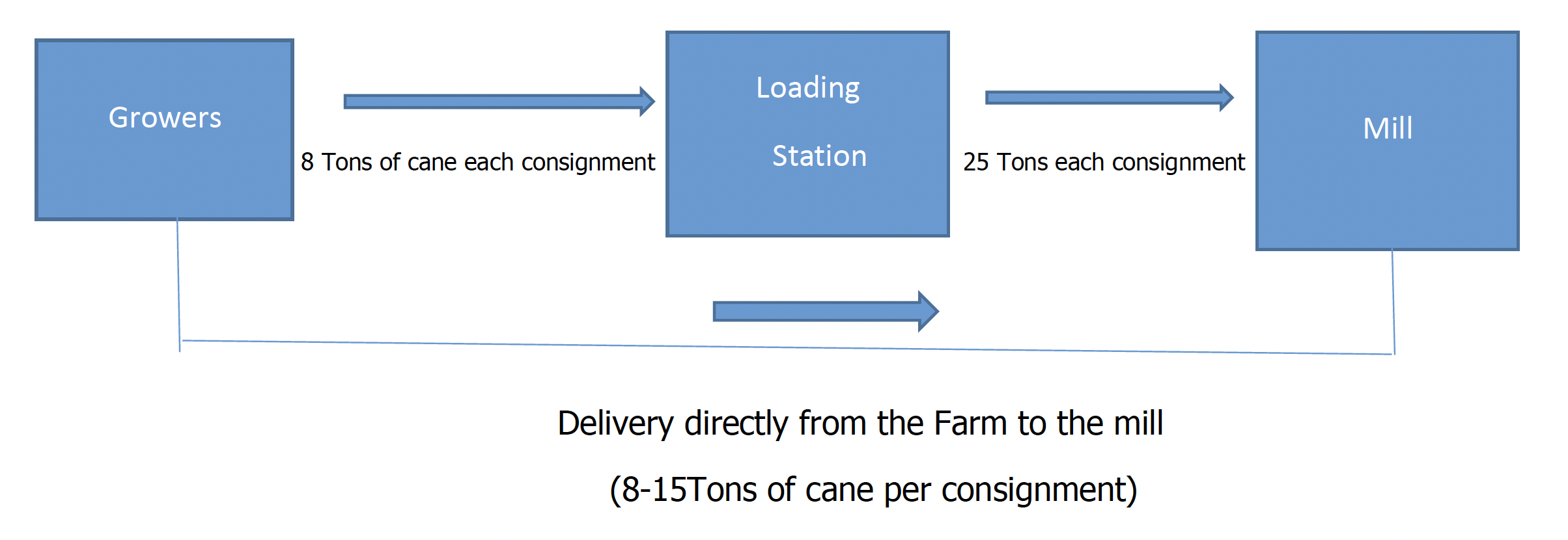

To address these challenges, most sugar mills have developed a "Loading Station Strategy" aimed at reducing transportation costs. A loading station is an area prepared specifically for cane loading, usually located close to the growers to facilitate a smooth supply of cane to the mills and reduce transportation costs borne by farmers. Approximately 1,500–2,500 tons of cane can be delivered from a loading station daily, with large trucks transporting a minimum of 25 tons per consignment. The loading station approach has helped mills reach target capacity utilization while enabling small-scale growers to lower their transport expenses.

Illustration of Loading Station

Conclusion

The success of the sugar industry relies on best practices in production, handling, and marketing. The re-enactment of the Kenya Sugar Board through the Sugar Act 2024, and the establishment of the Sugar (General) Regulations 2025 (Part V), outline the obligations governing all stakeholders in the transportation of sugarcane. However, there is still room for further improvement in overall industry efficiency and in the welfare of sugarcane farmers—particularly through the reduction of transportation costs, which remain a key component of total production expenses.